High Precision Timing Pulleys for Industrial Machinery

Our high precision timing pulleys are the perfect solution for industrial machinery that requires precise and reliable power transmission. Available in a wide range of tooth types including 1.5GT, GT2, 3GT, 5GT, MXL, XL, L, H, XH, XXH, 2M, 3M, 5M, 8M, 20M, T5, and T10, our timing pulleys can be customized to your specific requirements.

What makes our timing pulleys stand out?

We use only high-quality materials in the production of our timing pulleys, ensuring that they are durable and long-lasting. Our pulleys are also designed to be precise, with accurate tooth profiles that ensure smooth and efficient power transmission.

How long does it take to customize an order?

Our production lead time for custom made parts is typically between 3 and 30 days, depending on the availability of raw materials and the complexity of the customized item.

What industries can use our timing pulleys?

Our timing pulleys are suitable for use in a wide range of industries, including automotive, aerospace, manufacturing, and more. They are ideal for any application that requires precise power transmission.

Can I customize the tooth type and size?

Yes, we offer a wide range of tooth types and sizes to choose from, and we can also customize our timing pulleys to your specific requirements.

Do you offer after-sales support?

Yes, we offer comprehensive after-sales support to ensure that our customers are satisfied with their purchase. We also welcome feedback and suggestions for how we can improve our products and services.

At our company, we pride ourselves on offering a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, Roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products at competitive prices, and we are always happy to work with customers to meet their specific needs. Whether you need a standard product or a custom solution, we are here to help.

All content on this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our replacement parts can be perfectly adapted to the original spare parts, but if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

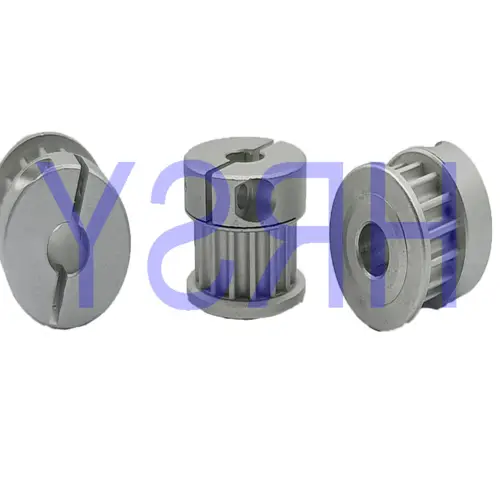

Introduction to the Performance Characteristics of Gt2 Pulley

Gt2 pulley is a mechanical component with many excellent performance characteristics that make it an ideal choice for a wide range of applications. The following are the main performance characteristics of Gt2 pulley:

- High Precision

- Low Noise

- High Wear Resistance

- High Transmission Efficiency

- High Tensile Strength

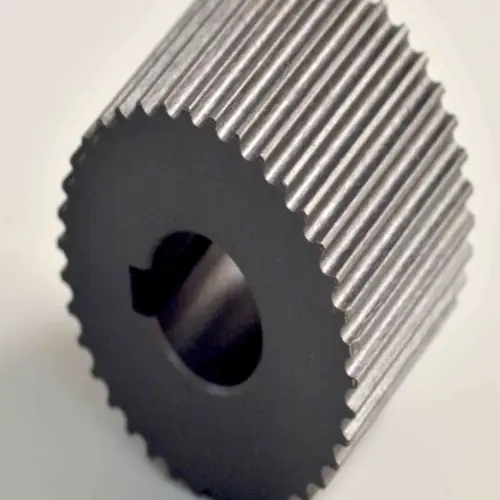

Types and Characteristics of Gt2 Pulley

Gt2 pulley can be divided into two types: single-row and double-row. Single-row Gt2 pulleys are suitable for low-load and low-speed applications, while double-row Gt2 pulleys are suitable for high-load and high-speed applications. The characteristics of Gt2 pulleys made of different materials are as follows:

- Aluminum Gt2 Pulleys: Lightweight, excellent heat dissipation, and corrosion resistance.

- Steel Gt2 Pulleys: High strength, wear resistance, and long service life.

- Plastic Gt2 Pulleys: Low noise, lightweight, and cost-effective.

Application of Gt2 Pulley

Gt2 pulley is widely used in various fields such as 3D Printing, CNC Machines, Robotics, Automated Conveyor Systems, and Medical Devices. In these fields, Gt2 pulley plays an essential role in transmitting power and motion. The following are the advantages of using Gt2 pulley in these fields:

- High precision and low noise make it suitable for 3D printing and CNC machines.

- High tensile strength and wear resistance make it suitable for robotics and automated conveyor systems.

- Low noise and lightweight make it suitable for medical devices.

Future Development Trends and Opportunities of Gt2 Pulley Products

With the increasing demand for precision and efficiency in various industries, Gt2 pulley products are expected to have a broad development prospect. The following are some development trends and opportunities of Gt2 pulley products:

- Development of high-precision and high-efficiency Gt2 pulleys.

- Application of new materials in Gt2 pulley products.

- Development of customized Gt2 pulley products to meet specific application requirements.

How to Choose a Suitable Gt2 Pulley

When choosing a suitable Gt2 pulley, several factors need to be considered, including Load Capacity, Material, Diameter and Size, Type of pulley, and Bore Size. The following is a brief analysis of these factors:

- Load Capacity: Choose a Gt2 pulley with a load capacity that matches the application requirements.

- Material: Choose a Gt2 pulley made of suitable material according to the application environment and requirements.

- Diameter and Size: Choose a Gt2 pulley with a suitable diameter and size that matches the application requirements.

- Type of Pulley: Choose a suitable type of pulley according to the application requirements, such as single-row or double-row pulley.

- Bore Size: Choose a Gt2 pulley with a bore size that matches the shaft diameter of the application.

Conclusion

Gt2 pulley is an important mechanical component with high precision, low noise, high wear resistance, high transmission efficiency, and high tensile strength. Gt2 pulleys made of different materials have their own characteristics and advantages. Gt2 pulley is widely used in various fields such as 3D Printing, CNC Machines, Robotics, Automated Conveyor Systems, and Medical Devices, and has a broad development prospect. When choosing a suitable Gt2 pulley, Load Capacity, Material, Diameter and Size, Type of pulley, and Bore Size need to be considered.